What is the difference between standard woven loop and unnapped loop?

Hook and loop fasteners consist of two components: the hook side and the unnapped loop (also known as the pile side or soft side). The loop side is crucial for engaging with the hooks. The market primarily offers two types of loop tapes: Standard Loop Tape and unnapped loop, which differ significantly in structure, performance, and application scenarios.

----------

1. Standard Loop Tape

Structure & Characteristics:

-Material: Typically woven or knitted from nylon or polyester yarn into a dense upright loop pile structure.

-Surface: Covered with fine loops; feels relatively soft but somewhat coarse.

-Key Issue:Prone to pilling, shedding, and fraying. During use—especially after repeated fastening, friction, or washing loops are easily snagged, broken, or worn by hooks, forming fuzz balls or loose fiber debris.

-Durability: Relatively low

-Appearance: Tends to look worn, messy, and aged after use.

-Advantages: Lower cost, mature production technology, good initial adhesion.

-Disadvantages: Susceptible to shedding/pilling, poor durability, easily appears worn, unsuitable for high-cleanliness environments.

-Typical Applications: Everyday clothing,bags, household items, toys, low-demand industrial fixing scenarios with low requirements for cleanliness and long-term durability.

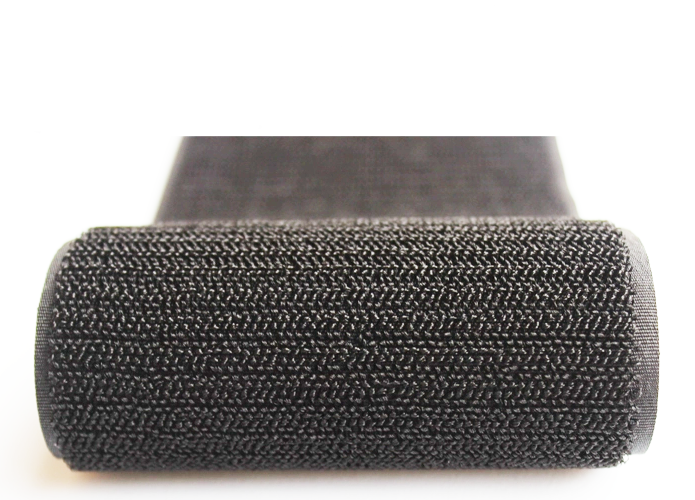

2. unnapped loop

- Material:Primarily nylon or polyester, but with different structures and/or specialized finishing processes.

- Surface Treatment: Key feature is extremely short, dense loops treated with processes like heat-setting, brushing, shearing, or melting.

-Key Advantage:Significantly reduces or eliminates pilling, shedding, and fraying. Loops resist snagging or breaking, maintaining a smooth, neat appearance.

-Durability: Greatly enhanced; withstands frequent fastening and offers extended lifespan with slow adhesion loss.

-Advantages: Resists pilling/shedding, high durability, maintains neat appearance, easy to clean, suitable for cleanrooms.

-Disadvantages:Usually higher cost than standard loop tape.

-Typical Applications: Medical devices (blood pressure cuffs, orthotic straps), electronics housings/cable management, automotive interiors, outdoor/military gear, cleanroom garments, high-end sports equipment, food processing machinery—any scenario requiring frequent/long-term use or high hygiene standards.